Kazuhide Kumakura, *Masanobu Hiroki, and Toshiki Makimoto

Materials Science Laboratory, *NTT Photonics Laboratories

@The quality of a GaN layer grown on sapphire substrates

by metalorganic vapor phase epitaxy (MOVPE) has been improved by the use of

low-temperature AlN or GaN buffer layers. Since the low-temperature deposited

layer is unstable, it is well-known that variously shaped islands were formed

as temperature increased. Therefore, it is difficult to grow the GaN layer

with sufficient quality or reproducibility, which is a quite severe problem

from the commercial point of view. Thus, it is important to find a new buffer

layer for GaN growth on sapphire substrates.

@Electron cyclotron resonance (ECR) plasma sputtering can easily deposit a

minute, uniform, and stable oxide or nitride layer on large area at room temperature.

An Al2O3 and an AlN can also be easily deposited by

ECR plasma sputtering at room temperature, and have very high melting points

above 2000, indicating that these materials could be used as a buffer layer

with good thermal stability. Therefore, we have proposed and demonstrated

the GaN growth on sapphire substrates with the ECR plasma sputtered layer

of Al2O3/graded-AlON/AlN/Al2O3

as a buffer layer instead of low-temperature AlN or GaN layer.

@We formed the buffer layers on c-face sapphire substrates by ECR plasma sputtering

at room temperature and used them as the growth substrates. The total thickness

of the buffer layers was 20 nm. We directly grew GaN on these substrates at

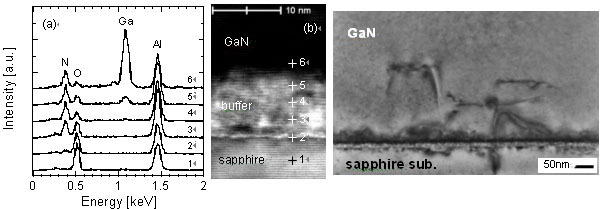

1000. Figures 1 (a) and (b) show the energy dispersion x-ray spectroscopy

(EDS) profiles and the cross-sectional transmission electron microscope (TEM)

image at the interface between the sapphire substrate and the GaN layer, respectively.

The peak intensities from nitrogen (N) increased gradually from the sapphire

substrate to GaN layer, and those from oxygen (O) decreased gradually, as

shown in Fig. 1 (a). These results indicate that we can easily form the nitride

layer by gradually changing the composition from the oxide layer.

@The cross-sectional bright-field TEM image showed that the dislocations were

bended at the initial stage of the growth as shown in Fig. 2, which indicated

the enhancement of the lateral growth, resulting in the decrease of dislocation

density to be 6.0 ~ 108 cm-2 in the GaN layer. The mobility

of the GaN layer was 540 cm2/VEs at the electron concentration

of 2 ~ 1017 cm-3. These results indicate that the quality

of the GaN layer grown using the ECR plasma sputtered buffer was comparable

or superior to the conventional grown GaN using the low temperature buffer

layer.

|

||

Figs. 1.

(a) The EDS profiles and (b) the cross-sectional TEM image at the

interface between the sapphire substrate and the GaN layer, respectively.

|

Fig. 2. Cross-sectional TEM image of the interface between the sapphire substrate and GaN layer. | |