Block Copolymer Lithography toward 16-nm-technology Nodes

Toru Yamaguchi and Hiroshi Yamaguchi

Physical Science Laboratory

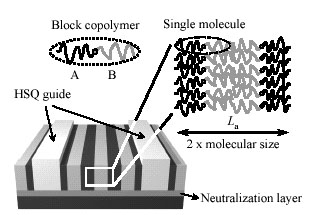

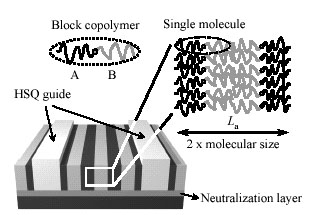

Block copolymer lithography (BCL) has attracted considerable attention

as a combined top-down/bottom-up approach to nanopatterning. It involves

the use of microphase-separated nanometer-sized domains of block copolymers

as lithography templates. In recent times, the significance of BCL in the

field of lithography is particularly increased due to the fact that top-down

lithography will soon be reaching its limit in the 22-nm regime, necessitating

the development of innovative technologies. BCL has great potential for

exceeding the resolution limit of the state-of-art top-down lithography

because its resolution is determined solely by the molecular size of the

block copolymer. The most important challenge in BCL is the achievement

of a strict control on the alignment of various microphase-separated domains.

Among these domains, vertical lamellar domains composed of alternating

stacked layers of two dissimilar polymer chain blocks A and B (Fig. 1)

have critical advantages as lithography templates for nanodevice fabrication

on account of their line shape, high aspect ratio, and wide flexibility

in pattern configuration. However, the difficulty encountered in the formation

of vertical lamellae was that the lamellar interface should be aligned

in two directions, perpendicular to the substrate surface and parallel

to the lithographically created features.

Here, we report our novel method of aligning lamellar domains by means

of graphoepitaxy using a resist pattern as an alignment guide [1]. Graphoepitaxy

is a technique that uses the surface topography of the substrate to direct

the epitaxial growth of the block copolymer film. The key to its success

is the combination of the neutralization of a bottom surface and the introduction

of a hydrophilic guiding pattern; this makes it possible to independently

control the surface affinity of the substrate surface and the sidewall

surface of the guiding pattern, which leads to the vertical orientation

and lateral alignment of lamellar domains, respectively (Fig. 1). We have

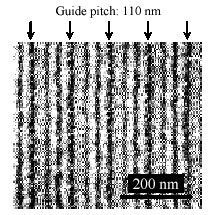

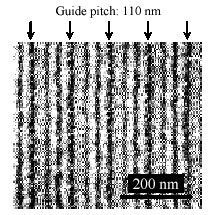

successfully demonstrated that the lateral alignment of the lamellar structure

of a symmetric poly(styrene-b-methyl

methacrylate) is achieved in confined spaces of about 3La (La:

laterally aligned lamellar period, La 〜 32 nm) between hydrogen silsesquioxane (HSQ) resist patterns on a neutral

surface (Fig. 2). It is important to consider that a lamellar structure

with a period shorter than the pitch of the guide pattern could be formed

by this method. We believe that the combination of the artificial layout

of the guide patterns and the best polymer materials could lead to a new

type of high-resolution lithographic technology in the 16-nm (1/2 La) regime.

[1] T. Yamaguchi and H. Yamaguchi, J. Photopolym. Sci. Technol. 19 (2006) 385.

|

|

|

| Fig. 1. |

Lateral alignment of lamellar domains. |

|

|

| Fig. 2. |

AFM phase image of aligned domains. |

|

[back] [Top] [Next]