Physical Science Laboratory

Three-dimensional (3D) nanostructures are now attracting great interest

because of their possible applications, such as to nanomechanical devices

and nanorobotics. To build various 3D nanostructures, we have devised and

are developing 3D electron beam (EB) lithography (3D-EBL). Although our

technique has some advantages, such as high resolution and fast fabrication,

it has so far shown drawbacks related to the electron scattering/proximity

effect and to the poor precision of structure/3D alignment, compared with

some other 3D fabrication techniques. We have newly devised two methods

in 3D-EBL to significantly improve the 3D alignment and reduce the proximity

effect.

When we make complicated 3D structures with this technique, the EB writes

from largely different directions and therefore should be well positioned

three-dimensionally; high accuracy of 3D alignment is necessary. The high

accuracy is achieved by using a transmission electron image to accurately

control sample rotation (< 1 mrad) and obtain sufficient accuracy of

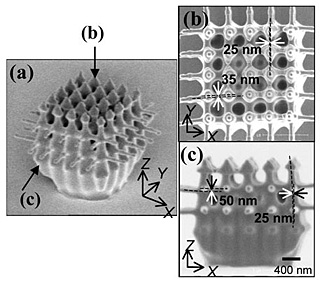

2D positioning of EB writing on a rotated sample [1]. In a 3D nanostructure

we created in negative resist (hydrogen silsesquioxane, HSQ), the 3D alignment

accuracy is on the order of 10 nm (Fig. 1). When we use positive resist,

the proximity effect is very serious. However, we have succeeded in suppressing

the proximity effect by leaving buffer areas (not exposed to EB) that surround

the target structure and have sizes similar to the range of fast secondary

electrons. As a result, we have reduced undesirable dissipated energy,

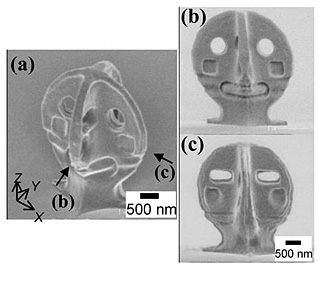

which changes vertically in the resist [2]. Figure 2 shows SEM images of

a 3D nanostructure in positive resist [poly(methyl methacrylate), PMMA],

which demonstrates a high aspect ratio and the great flexibility of structures

that can be created by the technique.

These methods will accelerate the development of 3D-EBL, making it promising for various nanotechnology applications.

This work was supported in part by KAKENHI (20246064).

[1] K. Yamazaki and H. Yamaguchi, J. Vac. Sci. Technol. B 26 (2008) 2529.

[2] K. Yamazaki and H. Yamaguchi, Appl. Phys. Exp. 1 (2008) 098001.

|

|

|||||

|

|