N-Face GaN (0001) Films with Hillock-free Smooth SurfacesGrown by Group-III-source Flow-rate Modulation Epitaxy

Low incorporation efficiency of nitrogen atoms has been a problem in the growth of nitride semiconductors, such as InN and InGaN, with the conventional group-III-face (0001) surface. Improvement of the crystal quality is expected by using N-face (0001) surface, since one can avoid re-evaporation of nitrogen compared with the group-III-face (0001) surface. However, a serious problem in N-face (0001) nitride films has been a high density of hillocks on the film surface. Here, we report that N-face GaN (0001) films with hillock-free smooth surfaces can be grown by group-III-source flow-rate modulation epitaxy (FME), wherein the flow-rates of group-III sources are sequentially modulated under a constant supply of NH3 [1].

In the group-III-source FME, NH3 was continuously supplied, while the group-III source (trimethylgallium or triethylgallium) was supplied at a higher (21 µmol/min) or lower

(10 µmol/min) flow rate alternately. The durations of the higher and lower flow-rate periods for one cycle were 1 and t s, respectively. The t value was varied from 0 to 10 s. Neither deposition nor etching of GaN occurs during the period of the lower flow rate t. Totally, 900 cycles were repeated, resulting in the total film thickness of approximately 450 nm.

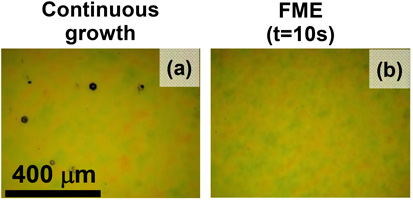

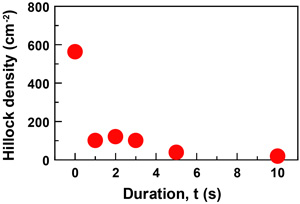

Figure 1 shows optical micrographs of N-face GaN (0001) films. Hillocks are observed in the samples grown by conventional continuous growth (t = 0). On the other hand, there are no hillocks on the surface prepared by group-III-source FME (t = 10 s). Hillock-free surfaces are achieved over almost the whole sample area (10 × 5 mm2) for t longer than 5 s. As shown in Fig. 2, the hillock density on the surface decreases drastically with increasing t. We have confirmed by cross-sectional transmission electron microscopy that there is a screw-type dislocation or micro-pipe at around the center of a hillock. This indicates that a hillock develops by spiral growth originating from a screw-type dislocation or micro-pipe. The reason for the decrease in hillock density by group-III-source FME is considered to be the enhancement of the surface migration of Ga atoms under low surface supersaturation during the lower Ga supply period t. The spiral growth rate of GaN rapidly decreases with decreasing surface supersaturation, while the step-flow growth rate decreases linearly. Therefore, under low surface supersaturation, the spiral growth rate can be lower than the step-flow growth one so that hillock formation is suppressed.

- [1] C. H. Lin, T. Akasaka, and H. Yamamoto, Jpn. J. Appl. Phys. 55, 04EJ01 (2016).

|

|

| Fig. 1. Optical micrographs of the surfaces of N-face GaN (0001) films grown by (a) conventional continuous growth (t = 0) and (b) group-III-source FME (t = 10 s). | Fig. 2. Hillock density on N-face GaN (0001) film surfaces plotted as a function of t. |