Optical Science Laboratory

Recently, nanoprint-nanoimprint technologies or scanning

probe microscope (SPM) lithography is attracting attentions for the fabrication

of nanostructures used in electronic or optical devices. Compared to conventional

"projection-type" lithography, these "contact-type" lithographies

have advantages in size and ease of operation. However, because the basic

concept involves transferring the surface shape of a mold, the pattern cannot

be modified in nanoprint-nanoimprint technologies. SPM lithography, in which

an electrochemical reaction is induced by a conductive probe tip, can provide

pattern flexibility. However, the throughput is still low. We are trying to

develop a lithography technique that can provide good throughput and flexibility

simultaneously.

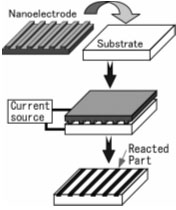

Figure 1 shows the principle of nanoelectrode lithography. A nanoelectrode

surface consists of a conductive area and an insulating area. The nanoelectrode

makes contact with the surface of a target. When a voltage is applied, current

flows between the nanoelectrode and the target material. Then, an electrochemical

reaction occurs on the target surface. For example, anodic oxidation of the

semiconductor, Si or GaAs, transfers the pattern to the target [1, 2]. Figure

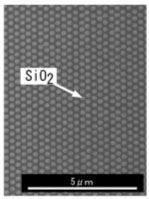

2 shows an example of Si substrate patterning by nanoelectrode lithography.

In Fig. 2, a nanoelectrode with a 300-nm-pitch dot pattern was used. The fabricated

oxide pattern worked well as a mask for wet and dry etching, which means that

resist-less patterning is possible. In addition, nanoelectrode lithography

does not deform the surface of the target during the patterning process. Therefore,

it will enable us to overwrite a pattern to fabricate a more complex pattern.

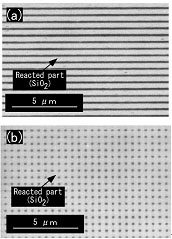

Figure 3 shows checked pattern fabricated by repeating the process with a

line-and-space (L/S) pattern [3].

As shown here, nanoelectrode lithography has some advantages, such as direct

fabrication of the etching mask and modification of fabricated patterns by

combining this approach with another lithographic technique. In addition,

the lithography process can directly fabricate patterns defined by chemical

characteristics such as hydrophilic or hydrophobic properties. These pattern

may be used as templates for selective growth of semiconductors. We will apply

nanoelectrode lithography for patterning of metal layers or resist layers

on a substrate to prove the generality of the technique.

[1] A. Yokoo, Jpn., J. Appl., Phys., 42, L92 (2003)

[2] A. Yokoo, S. Sasaki, Jpn., J. Appl., Phys., 44, 1119 (2005)

[3] A. Yokoo, J. Vac. Sci. Technol. B, 21, 2966 (2003)

|

|

|

|

Fig. 1 Nanoelectrode lithography |

Fig. 2 Fabricated pattern on Si |

Fig. 3 Multiple patterning (a) after 1st procedure (b) after 2nd procedure |