Hiroo Omi and Tomoaki Kawamura

Materials Science Laboratory

Nanoscale ultra-thin Si films exhibit quantum size effects when their

thickness becomes smaller than several nanometers. In order to control

nanoscale silicon devices based on the quantum size effect, it is essential

to achieve high-quality silicon nanolayers without strain distribution.

Ultrathin silicon nanolayers are usually fabricated by thermal oxidation

and HF etchback processes on silicon-on-insulator wafers. In this method,

the silicon layers are subjected to strain due to the difference in the

thermal expansion coefficients between Si and SiO2 during the thermal silicon oxidation. As a result, the strain significantly

increases as the silicon nanolayers become thinner, as has been observed

by X-ray diffraction and Raman spectroscopy. However, with these conventional

apparatuses, we can only detect information about the average lattice strain

in the silicon nanolayers; it is difficult to detect information about

the localized strains existing on the surface of the thin silicon nanolayers

or at the Si/SiO2 interfaces.

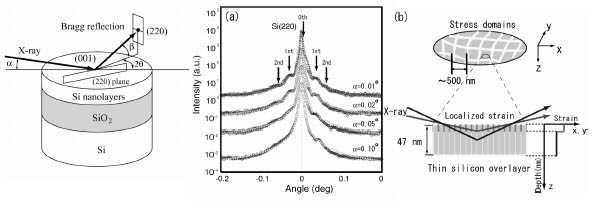

We developed a new apparatus for grazing incidence X-ray diffraction

(GIXD) using the syncrotron radiation source at SPring-8 (Fig. 1) and established

a method for evaluating such spatially localized strain on a surface. The

new apparatus can be used at the incident angle below the critical angle

of Si (0.18°). Consequently, for the first time, we succeeded in detecting

small strain localized on the surface of silicon nanolayers with this apparatus.

We probed in depth the strain on the surface of the Si nanolayers by

changing the incident angle of GIXD. The diffraction patterns obtained

at the incidence angles of 0.01° and 0.1° are originated from 2

nm and 6 nm in depth from the lattice of surface region (Fig. 2(a)). From

the intensity analysis based on the two-layered-strain model (two layers

with different states of strain), we found that the surface region of the

silicon nanolayers has finite strain domains and that the degree of the

strain is on order of 10-4 (Fig. 2(b)). Moreover, by applying this method to a thermally annealed

sample, we found that a high annealing temperature of 1000℃ is required

in order to obtain uniform silicon nanolayers on which strain does not

localize.

[1] H. Omi, et al., Appl. Phys. Lett. 86 (2005) 263112.

|

||||||

|

|

|||||