A novel semiconductor device that operates by using microscopic vibrations

- Digital operations by the “vibrational motion” of a spring thinner than a human hair -

NTT Basic Research Laboratories have developed the world's first semiconductor device based on a novel principle that performs digital operations by using a spring thinner than a human hair on a semiconductor chip. At the heart of the developed device is a tiny flat spring that is 250 µm long, 85 µm wide and 1.4 µm thick. By assigning the phase of its microscopic vibration (10 nm amplitude) to the bit information "0" and "1" , fundamental one bit data operations have been achieved. Since the newly developed device operates by using the microscopic vibration of a flat spring, a computer employing this device has the potential to realize power consumption several orders lower than conventional transistor-based integrated circuits. Thus such a computer is expected to give rise to a new information processing system that meets the demand for a low energy computer.

This achievement will be published in the electronic edition of the UK science journal "Nature Nanotechnology" on April 13 as the world's first proposal and demonstration of a concrete method for digital data processing that uses a nano-machine.

=> Nanostructure Technology Research Group

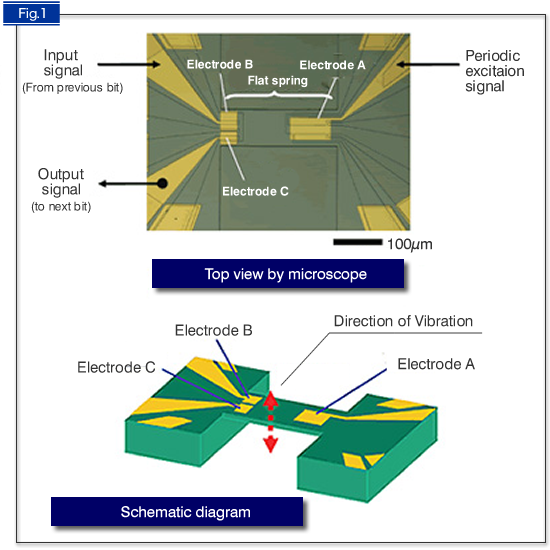

Fig. 1 Structure of device

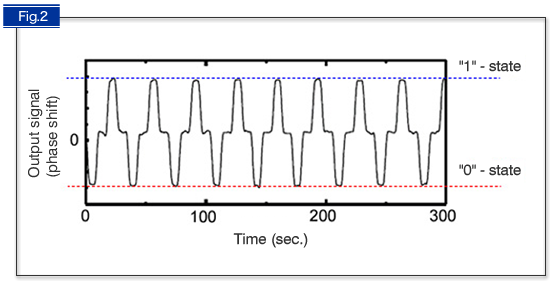

By applying a small alternating voltage to electrode A, force is generated along the flat spring. This force yields a microscopic vibration which can be detected. The temporal evolution of the spring's bending motion to the applied voltage is used to encode the bit data, namely the sequences "center → bottom → center → top" and "center → top → center → bottom" correspond to the bit states "0" and "1", respectively.

Fig. 2 Output for alternate input signals of "0" and "1"

To apply this device to actual digital processing, a concrete method is needed whereby a spring receives bit information from an adjacent spring and passes it onto another one. In this work, we succeeded in completing the following sequence. First, pseudo-information is inputted into electrode B in Fig.1. Next the information is stored in the flat spring as its vibration by adding a periodic signal to electrode A. And finally the stored bit is extracted from electrode C as an electric signal. By linking multiple devices in this way, digital operations in a flat spring can actually be achieved.